- Products

- Secondary Battery Separator

Secondary Battery Separator

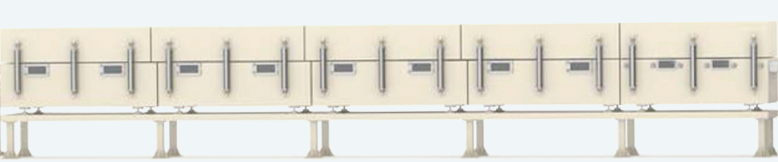

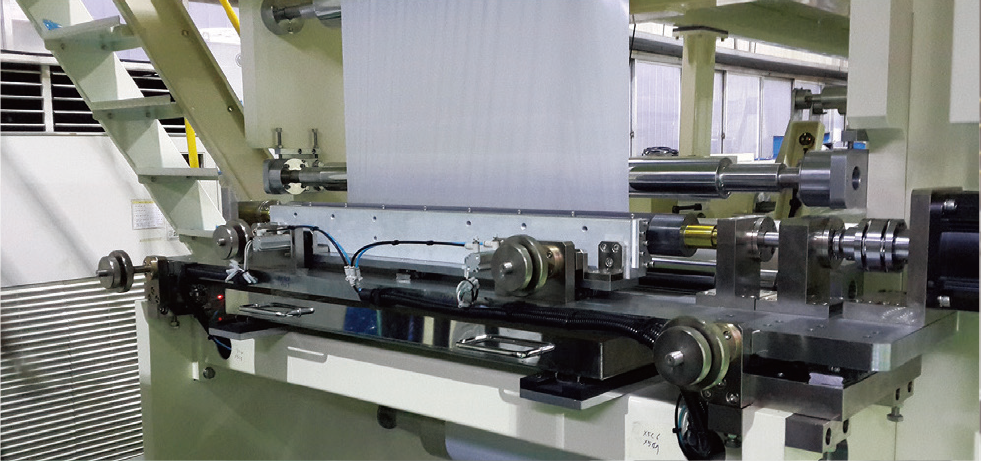

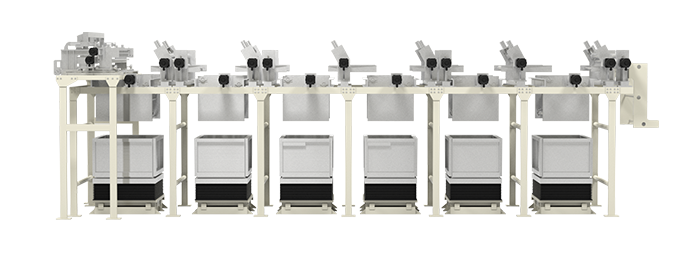

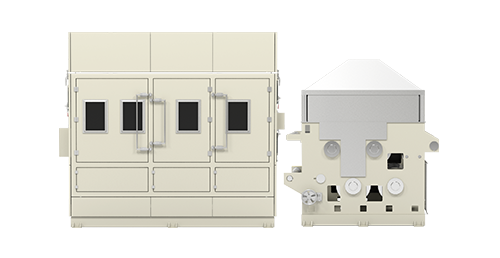

Separator Film Coating Machine

Coating with ceramic slurry or other solution(PVDF, ARAMID, etc.) using the Gravure roll coater

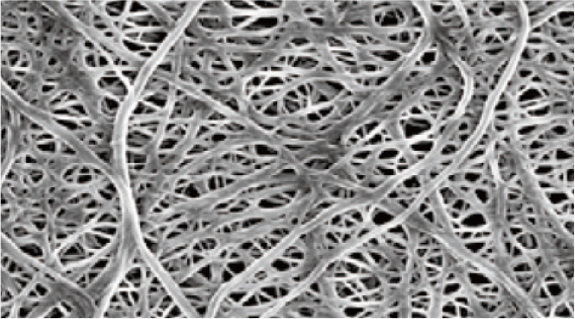

PVDF Coating

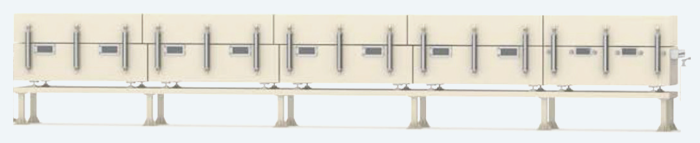

Process flow (Jacket Roller type oven)

Product Specification

| Machine speed | Max. 120m/min | Width of Film | 500mm ~ 1400mm |

|---|---|---|---|

| Coating Thickness | 1~5㎛ | Diameter on Unwinding Side | Max. 400mm |

| Coating Head | Gravure (both sides) | Diameter on Winding Side | Max. 600mm |

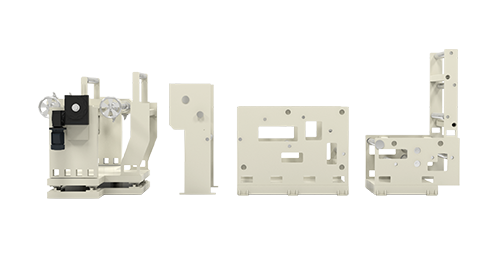

- - Web Transfer Device

- - Coating Device

- - Drying Device

- - Surface before and after coding

PVDF Coating

-

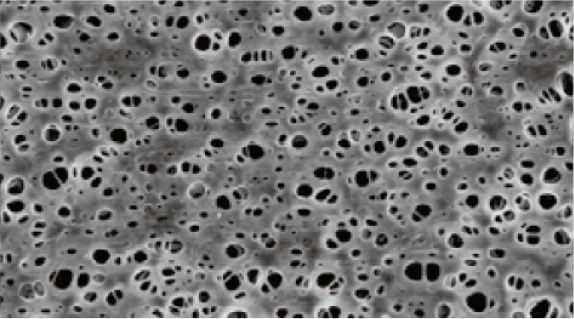

Before Coating

Surface

Surface

-

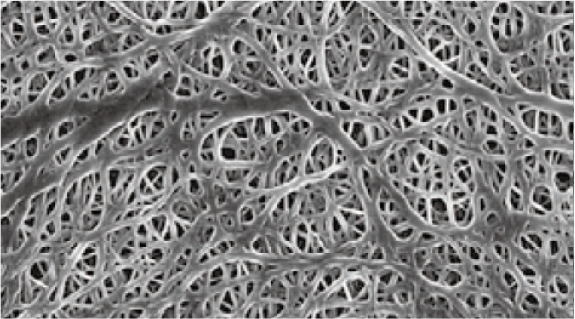

After Coating

Surface

Surface

-

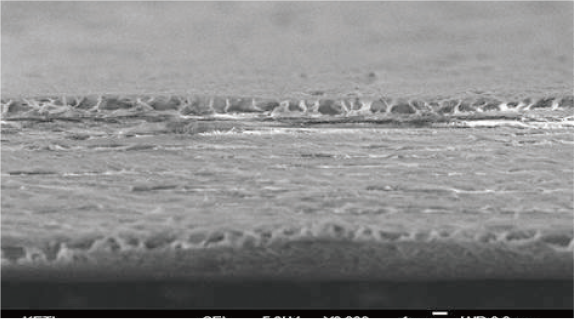

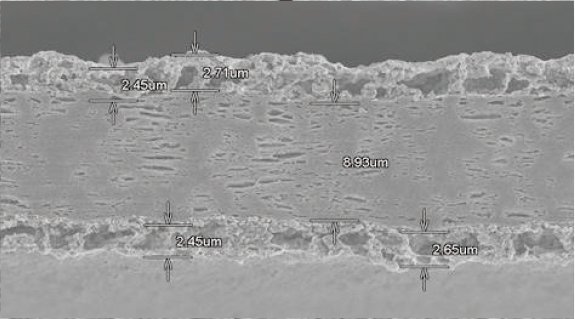

Cross Section

Cross Section

Ceramic Coating

Process flow (Air floating type Oven)

Product Specification (Air floating type Oven)

| Machine speed | Max.120m/min | Width of Film | Max. 600mm ~ 1400mm |

|---|---|---|---|

| Coating Thickness | 2~4㎛ | Diameter on Unwinding Side | Max. 400mm |

| Coating Head | Mayer(wire) bar (both sides) | Diameter on Winding Side | Max. 600mm |

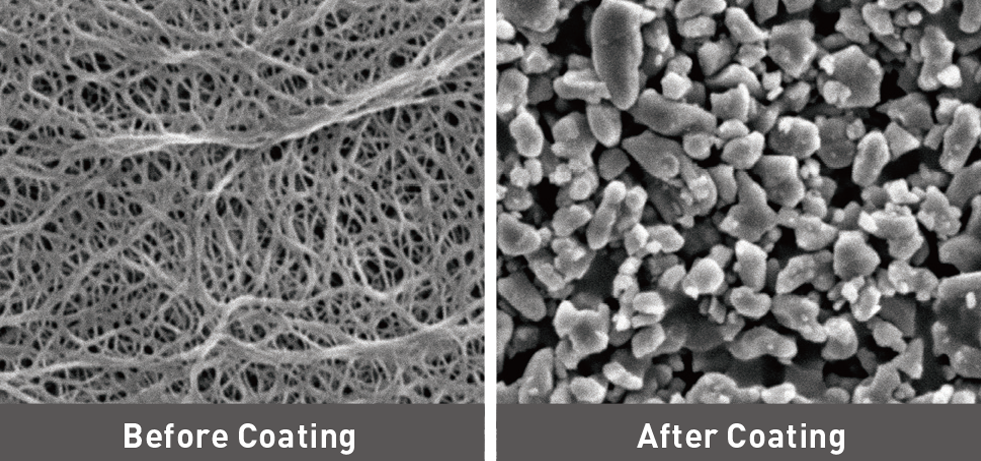

Ceramic Coating

-

Before Coating

Surface

Surface

-

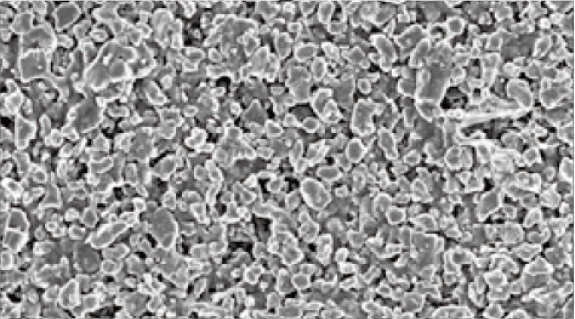

After Coating

Surface

Surface

-

Cross Section

Cross Section

Unwinder & Inspection

Coating & Washing

Dryer & Setting

Inspection & Rewinder

Unwinder

Coating

Dryer

Inspection